One of the main challenges with indoor cannabis cultivation is maintaining proper air quality. Grow rooms often have limited ventilation and high humidity, which can create conditions that are conducive to mold, mildew, and other harmful microorganisms. In addition, many plants release volatile organic compounds (VOCs) and odors that can be unpleasant and potentially harmful if inhaled.

Grow room air filtration systems and air purifiers are both designed to improve indoor air quality and can be effective for maintaining clean and healthy air in a grow room. However, they are built to address different types of pollutants and there are several key differences in terms of how each of them clean the air.

Grow room air filtration systems are specifically designed to filter and clean the air in indoor grow rooms where plants are cultivated and are typically more powerful than air purifiers. These systems are important for maintaining healthy plant growth and preventing the spread of plant diseases and they remove a wide range of pollutants, including odors and gases.

Air filtration systems are built to handle the larger volume of air in a grow room and are also often customizable, allowing you to choose the types of filters you need based on the specific needs of your plants.

Grow room air filtration is the process of capturing bacteria, VOCs, mold spores, and other air contaminants by using a centrifugal-type blower and specialized filter media. The blades or impellers of the blower drag air in a circular motion with the centrifugal force pushing the airflow out of the fan and outwards to achieve air exchanges.

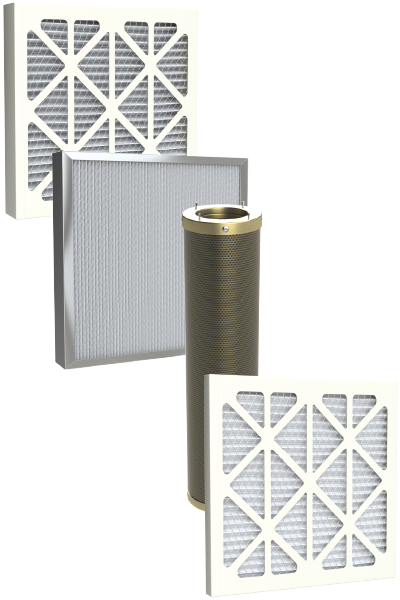

Along with the blower, air filtration systems also utilize one or more types of specialized filter media such as HEPA (high-efficiency particulate air) filters, activated carbon filters, or both to capture and filter submicron, micron, small, and large-sized contaminants from the air stream.

Grow room air filters are typically made of materials such as fiberglass, polyester, or cotton, and can be found in various sizes and types, such as pleated, flat, or high-efficiency. The effectiveness of air filtration depends on the type and quality of the filter, as well as the airflow rate and the size of the particles being filtered.

The type of filter used in a grow room air filtration system will depend on the specific needs of the plants and the type of contaminants present in the environment. Carbon filters are commonly used to remove VOCs and odors, while HEPA filters are effective at capturing small particles such as mold spores and bacteria.

HEPA Filters

HEPA filters used in grow rooms, indoor gardening, or horticulture capture small airborne contaminants to provide a clean and controlled environment for plants to grow. A grow room HEPA filter typically works in combination with a pre-filter that captures larger particles and extends the life of the HEPA filter. The HEPA filter itself is made up of densely packed fibers that trap particles as air flows through it.

Using a grow room HEPA filter can help prevent the spread of pests and diseases, improve plant growth and yield, and ensure a healthy environment for growers and their plants.

CleanLeaf Clean Room Series units feature:

✓ Pleated pre-filter made of fiber media with a MERV 10 rating to protect the primary filter from getting clogged with larger particulate.

✓ 95% efficient 8-pocket bag filter with a MERV 15 rating to capture small to medium-sized particulate, extending the life of the HEPA filter.

✓ 99.99% efficient high-capacity V-bank HEPA filter to capture even the smallest contaminants. The V-shaped channels increase the surface area that air comes into contact with, without sacrificing airflow.

Carbon Filters

Carbon filters are commonly utilized in grow rooms to remove unwanted odors and VOCs. Carbon filters work by using activated carbon to absorb and neutralize odors and other airborne contaminants. As air flows through the filter, the activated carbon traps contaminants and removes odors from the airstream.

Using a carbon filter in a grow room can be particularly important for growers who are cultivating plants with strong odors, such as cannabis or certain types of herbs.

CleanLeaf Odor Control Series units feature:

✓ Pre-filter made of fiber media with a MERV 10 rating to protect the primary filter from getting clogged with larger particulate.

✓ Odor-absorbing carbon canister filled with 7 lbs of activated carbon to capture and absorb even the most stubborn odors from your garden.

✓ Pleated after-filter made of fiber media with a MERV 10 rating provides the airstream with one last step of filtration before circulating it back into your garden.

HEPA & Carbon Filters

When selecting a HEPA filter system, carbon filter system, or a system that incorporates both, it's important to consider the size of the grow room, the airflow rate, and the type of plants being grown to ensure that the air filtration system is appropriately sized and effective at removing contaminants.

To achieve the cleanest air possible while simultaneously controlling odors, we recommend air filtration systems from the CleanLeaf All-Inclusive Series — these systems are equipped with HEPA and carbon filters to provide optimal grow room protection.

CleanLeaf All-Inclusive units feature:

✓ HEPA-saving pre-filter made of fiber media with a MERV 10 rating to protect the HEPA filter from getting clogged with larger particulate.

✓ True HEPA filter with 95% D.O.P. @ 0.3 microns to capture mold and mildew and other contaminants, protecting your garden from powdery mildew, cross-pollenation, and more.

✓ Odor-absorbing carbon canister filled with 7 lbs of activated carbon to capture and absorb even the most stubborn odors from your garden.

✓ Pleated after-filter made of fiber media with a MERV 10 rating provides the airstream with one last step of filtration before circulating it back into your grow room.

While it's true that HEPA filters are highly effective at capturing airborne contaminants, they are not able to effectively remove odors. On the other hand, grow room air filtration systems equipped with carbon filters are excellent at controlling odors and VOCs because they are porous, and offer a large surface area for the adsorption of contaminants.

During adsorption, the odors and VOCs that are drawn into the air filtration system stick to the outside of the carbon.

Air filtration systems can be installed or hung and are also made available as portable units, and are often used in commercial settings. By placing air filtration systems in a pattern, they work together to create circular airflow throughout grow rooms.

Each air filtration system has a catch-and-throw distance to establish how far apart the systems should be placed to properly push air from one unit to the next. The amount of times that the airflow is circulated through this pattern is an air exchange. The number of air exchanges required will vary on the size of the room and application — for example, a standard office requires around six air exchanges per hour, while a larger-sized room may require up to eight.

When it comes to airflow, understanding CFM (cubic feet per minute) is important because it represents the amount of air that an air filtration system can move or circulate in one minute. When the CFM rating is higher, it indicates a more powerful air filtration system that can move more air and filter more contaminants.

CFM requirements vary based on several factors, including the size of the grow room, the type and volume of contaminants present, and the needs of the plants in the space. In general, a higher CFM rating indicates a more powerful air filtration system that can move more air and filter out more contaminants.

When selecting a grow room air filtration system, it's important to consider the recommended CFM rating for the specific application. A system that is too small for the space may not be effective at removing contaminants or providing adequate filtration, while a system that is too large can be inefficient and increase operating costs.

Proper air filtration is essential for maintaining healthy plants and establishing a productive indoor growing environment. By investing in a high-quality air filtration system and following these tips, you can ensure that your grow room air is clean and healthy for your plants to thrive:

✓ Use a high-quality air filtration system

Invest in a good-quality air filtration system that are designed for grow rooms.

✓ Choose the right type of filter

Understand your grow room needs and priorities — are odors the primary concern? Do you need the cleanest possible air? Or both?

✓ Size your filtration system appropriately

The size of your filtration system should be based on the size of your grow room. Make sure to choose a system that can handle the amount of air in your room and run it at the recommended capacity.

✓ Keep your grow room clean

Regularly clean your grow room to reduce the amount of dust and other particles that can accumulate in the air. This will help your filtration system work more effectively.

In addition to filtration, grow room air filtration systems can help to create a clean and controlled environment for plant growth, which can improve yields and overall plant health.

It's important to select an appropriate air filtration system for your grow room, as different plants have different requirements and may be more sensitive to certain pollutants or environmental factors. Regular maintenance, such as replacing filters, is important for ensuring optimal performance and preventing the buildup of harmful contaminants.

Unlike air filtration systems, air purifiers use filters and specialized technologies — such as ionization, ultraviolet light, or photocatalytic oxidation, to kill or neutralize airborne pathogens, allergens, dust, pet dander, smoke, and other contaminants. Air purifiers can be effective in very small grow rooms or gardens, but not all purification systems are manufactured to operate the same.

HEPA Air Purifiers

Some air purifiers on the market are simply HEPA filters equipped with a low-powered fan. HEPA air purifiers works by using fans to draw air through the filter, which traps particles and pollutants in the filter media. This type of air filter setup can theoretically remove at least 99.97% of dust, pollen, mold, bacteria, and any airborne particles with a size of 0.3 microns (µm) — but when utilized in a HEPA air purifier, the amount of space that can be effectively purified is limited.

Ozone Air Purifiers

Ozone air purifiers can be effective at removing certain air contaminants, like smoke and odors, they can also be harmful to health. Ozone gas can irritate the lungs and aggravate asthma symptoms, while long-term exposure can lead to respiratory issues and other health problems.

The US Environmental Protection Agency (EPA) issued a warning against the use of ozone air purifiers, stating that "ozone generators that are sold as air cleaners intentionally produce the gas ozone. Often the vendors of ozone generators make statements and distribute material that lead the public to believe that these devices are always safe and effective in controlling indoor air pollution. For almost a century, health professionals have refuted these claims." Because of the safety risks, we do not recommend ozone air purifiers.

Photocatalytic (PCO) Air Purifiers

Photocatalytic air purifiers use a combination of UV-C light and a photocatalytic filter to remove pollutants from the air. These air purifiers use a process called photocatalysis, which involves the activation of a photocatalyst (usually titanium dioxide) by UV-C light to break down pollutants in the air.

When air contaminants come into contact with the photocatalyst, they are oxidized and converted into nontoxic substances, such as water and carbon dioxide. This process is effective in stationary applications to remove a wide range of pollutants, including volatile organic compounds (VOCs), bacteria, and viruses, however, there are serious concerns regarding efficiency, particulate removal, and harmful by-products from the unfinished breakdown of VOCs in airflow applications.

The effectiveness of these systems can vary depending on the specific contaminants present in the airstream and the design and quality of the air purifier.

While PCO technology has been proven to be effective, the risk of negative health effects and low efficiency make HEPA air filtration systems the safest solution for grow rooms and gardens.

It is worth considering the size of your space, your budget, and any specific concerns you have about indoor air quality when choosing between an air filtration system and an air purifier. It is important to choose the right technology and filter based on the application to achieve the necessary level of air quality.

Grow room air filtration systems remove a wider range of airborne contaminants including particles, gases, and odors when compared to air purifiers and are typically used in larger spaces such as commercial buildings and industrial facilities, where a lot of people are present and/ or where the application generates contaminants.

Ultimately, the best choice for your grow room will depend on the specific needs of your plants and the size of your space. If you are unsure which option is best for you, consider consulting with a specialists on our team who can help you choose the right air filtration or purifier system for your grow room needs.

You may also like:

• Cannabis Microbes Regulations

• PCO vs. HEPA in Grow Rooms

• How to Maintain Grow Room Quality?