When it comes to indoor growing facilities, there are four major threats - mold, pollen, pests, and bacteria.

Growers often rely on ventilation to help improve and maintain grow room air quality but honestly, these systems aren't designed to protect plants from disastrous threats.

Proper grow room air filtration helps prevent powdery mildew and cross-pollination and restricts airborne dust and pests from settling on the canopy.

When purchasing grow room air filtration systems, it's important to note that aggressive oxidizers are known to emit byproducts that are harmful to humans and plants.

CleanLeaf Air Filtration Systems provide a safer, more effective and efficient solution to controlling grow room threats, but choosing between HEPA and PCO technologies can be difficult with the overwhelming amount of conflicting information available.

So what technology is right for you?

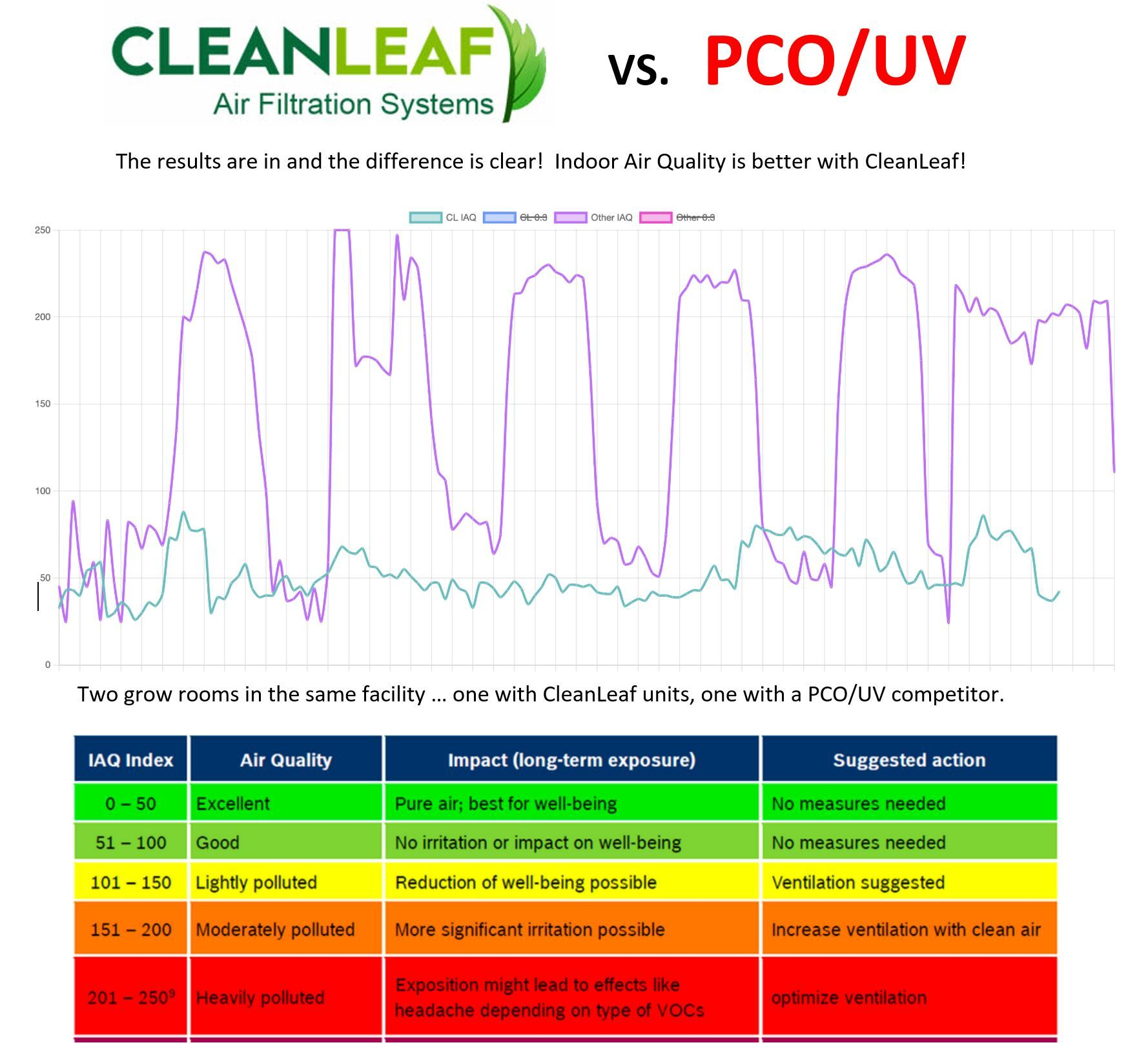

Two grow rooms in the same facility were tested with CleanLeaf units installed in one and a PCO/UV competitor operating in the other.

The green data set in the double line graph represents CleanLeaf Air Filtration Systems, and the purple data set represents the PCO/UV competitor.

The results show that indoor air quality is better with CleanLeaf! Our units keep the IAQ index below 100, providing excellent air quality that is best for well-being and the suggested action is no additional measures needed.

Our competitors results range mainly above 100 up into the 250 range which means the IAQ index is heavily polluted when using PCO/UV technology.

Although PCO has proven effective in stationary applications, there are serious concerns regarding efficiency, particulate removal, and harmful by-products from the unfinished breakdown of VOC’s in airflow applications.

In order for VOC’s to be completely broke down into harmless carbon dioxide and water, the UV light, catalyst, and speed of the contaminated air must be perfect to produce any sort of significant efficiency.

Most alarming, the by-products from the unfinished breakdown of VOC’s during testing have produced up to 4x the amount of Formaldehyde in the air, a known human carcinogen.

A 2015 Concordia University study summary concluded, “Imagine if, in an effort to clean the air more efficiently, you were involuntarily introducing chemicals more dangerous than the ones you were trying to scrub. Researchers have found that this exact situation is happening with a type of air filter called photocatalytic oxidation, a product already on the market.”

With product testing becoming the norm, keeping airborne dust and mold off the plants is critical; something PCO technology is not designed to do. Although some pollen and mold will be killed via photocatalytic oxidation, the particulate remains in the air.

HEPA filters trap airborne particulate within the filter, creating a surgical level clean room environment.

According to the EPA summary of PCO air cleaners, “PCO cleaners use UV lamps along with a substance, called a catalyst, that reacts with light. These cleaners are designed to destroy gaseous pollutants by changing them into harmless products, but they are not designed to remove particulates. The usefulness of PCO cleaners in homes is limited because currently available catalysts are ineffective in destroying gaseous pollutants in indoor air.”

High-efficiency particulate air filters (HEPA) were originally designed in the 1940’s for the Manhattan project, where the first atomic bomb was developed during World War II. A major advancement in air filtration technology, the filter solved a critical need to control very small particles which had become contaminated by nuclear radioactive sources.

Also known as absolute filters, they remove 99.99% of particulate down to .3 micron, the major threats to indoor grow rooms being 1 micron and larger.

For reference, the human eye cannot see anything under 40-50 micron. Due to its effectiveness, HEPA filters have become the standard for any process requiring the ultimate in air filtration.

Although PCO technology has proven effective at preventing mold growth within the HVAC duct, the possible negative health effects and low efficiency make HEPA filtration the superior solution for indoor grow rooms.

You may also like:

• 5 Ways to Make Your Grow Room More Sustainable

• Cannabis Cultivation & It's Large Energy Footprint

• RI's Finest Install